KEEN Utility Boots

We are pleased to partner with KEEN Utility to bring you a boot giveaway. I also want to share with you what has made my boot buying an easier process with the best results for my needs. It’s the first tool I use everyday.

I have been on a search for the Holy Grail of boots for many years. I feel that boots are one of the most important tools in our arsenal. As such we want the best tool for the job.

Sometimes we feel that boots are a one size fits all solution. This could be true in some cases. If you work in a shop or factory and do the same task every day you can probably keep buying the boots you are currently wearing and they will serve you well every season year after year.

One Tool Is Never Enough

For people like me who never know what the next job might be, one boot will not do. I do remodeling and fire and water damage restoration. The job is different almost every day. One day I may be walking in several inches of water. Another day I may be jackhammering concrete or shoveling out a crawl space. I can go weeks working inside a finished home tearing out and replacing cabinets, doors, trim, tile and drywall. I may be working outside in the snow and mud.

Due to this diversity and because I have some pretty harsh foot and ankle problems, I use different boots for different days. Sometimes I need a waterproof boot. Sometimes I need a boot that breathes. I normally wear a safety toe but I don’t have to every day.

One thing I do need every day is firm support for my feet. I want comfort but more than that I need my foot to be held in a position that keeps my anatomy in proper alignment. I have really flat feet. In addition, I have broken my ankle. I have torn ligaments on more than one occasion. Over the years I have been to several podiatrists. They have prescribed custom orthotic inserts. I have even had surgery to correct some of the problems. Nothing has worked better than having the right boots with the right amount of support.

No boot company has helped my feet feel better every day than KEEN Utility. Not Redwing, not Thorogood, not Wolverine, not Carolina, not Timberland Pro and certainly not any of the cheaper brands. KEEN Utility has allowed me to stay on my feet longer without severe foot and ankle pain. Now I must say I can’t wear every boot they make but there are quite a few.

There are basically three methods KEEN Utility uses to construct their boots.

Not All Boots Are Made Alike

The lightest and least expensive method is cementing. They attach the upper last to the midsole and sole using high quality cement adhesives.

Support Needed

The next more durable method which we have actually gotten to try our hand at in Portland, Oregon is the Direct Attach method. An upper last and a sole are held in place in a machine. Hot liquid Polyurethane is then injected between the two parts to form the midsole and basically vulcanize the parts together as one through a chemical bond.

The most durable method of constructing KEEN Utility boots is the Goodyear Welt method. Welt Construction is a tried and true method of construction and the oldest practice for footwear manufacturing. How is it built? First, a welt (A heavy strip of leather, rubber or plastic) is stitched to the bottom edge of the upper. Then, a strip of canvas or leather is cemented to the insole of the shoe as a point of attachment for the sole. After that, the space that is enclosed by the welt is filled with cork or another material that is breathable. Finally, the outsole is both cemented and stitched to the welt. Not only is it stronger and more durable, it is also possible to resole. This adds even more to the durability.

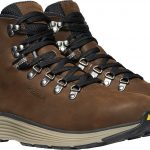

A Great Example of a Cemented Boot

When I am working inside I don’t need a heavy duty boot. I can opt for a super comfortable pair like the Manchester. The mid soles are very supportive but more comfortable than all of my top of the line running shoes. The midsole has a special blend of materials to absorb shock without crushing down quickly like regular EVA. The supreme comfort has helped me to go longer than any other boot ever.

- KEEN Utility Manchester

- KEEN Utility Manchester

- KEEN Utility Manchester

- KEEN Utility Manchester

The Manchesters are also waterproof so they are great for the cold, wet seasons. KEEN Utility sent me a pair but I liked them so much I bought two more. I bought one soft toe and one safety toe.

There are more than a few battle scars on mine. I have scuffed the toes a bit from being on my knees more than I like. I have also gouged them a few places from working on scaffolding. The soles are wearing a little faster than most other KEEN Utility boots I have owned. I do miss the big protective toe cap but I do like the looks of these without it. Even so, I will buy them again and again for the supreme comfort.

Boots With Direct Attachment

The only boots I have that are made with the injection molding process are the Logandales. They are very comfortable. The uppers are part leather and part synthetic. The midsole is a very resilient PU foam. These are medium duty boots which should last longer than the Manchesters in medium to heavy work. All the boots made in the Portland, OR facility are built with the direct attach process.

We actually got to have a hand in building our own pair in Portland, Oregon. It was a very interesting process. I am glad to see them bringing many jobs back to the USA.

To begin the process we received a pre sewn upper and a lower rubber sole. We then loaded the upper onto a very hard plastic foot shaped last. Next we loaded the outer sole into a mold. The last is then suspended just above the sole inside the mold. Hot liquid PU foam is injected between the upper and the sole creating the midsole area effectively making them one unit. After cooling, the boot is released from the mold for final trimming and packaging. We skipped the packaging since we didn’t need another box and had no extra room for the plane ride home.

- KEEN Utility Logandale

- KEEN Utility Logandale

- KEEN Utility Logandale

- KEEN Utility Logandale

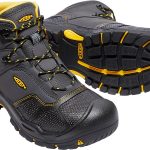

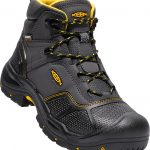

Heavy Duty But Not Heavy

On heavier days like demolition day or when I am running a jackhammer to tear out concrete or tile I try to wear a heavier duty boot. For the last few years that has been the Tacoma and the Glendale. These heavier boots are built with a Goodyear welt sole. This type of boot is the most durable boot construction. They are discontinued. They have been replaced by the Cincinnati and Philadelphia.

- KEEN Utility Cincinnati

- KEEN Utility Cincinnati

- KEEN Utility Cincinnati

- KEEN Utility Cincinnati

About three months ago I got a pair of the all new Cincinnati boots. They have quickly become the one boot I would own if I could only have one pair. The Cincinnati 6” wedge sole carbon fiber toe boot is made with the KEEN luftcell midsole. It is an air infused PU that is designed to provide maximum cushion and support. On my feet they are easily 95% as comfortable as the Manchesters but even more supportive on those long days. Cincinnati is built to hold up much longer. They are heavy duty without being too heavy.

The Cincinnati is made with the highest quality leather offered in a work boot. It is nice and thick while still being supple KEEN Utility calls it barnyard resistant leather. It is resistant to oleic acid, urea, sodium chloride, and ammonium hydroxide in order to extend the life of the boot. The inside is nicely finished with a padded liner. It adds to my all day comfort level with reassuring ankle support.

This is by no means a comprehensive review of KEEN Utility boots. They have an incredibly diverse line up of high quality boots. I was glad to learn of the different methods of building boots. It was also enlightening to see why there are different types out there for light, medium and heavy duty use. Hopefully this will help you to make more informed decisions when comparing boots.

Great evaluation at the boots. Keen makes some splendid boots. Would simply love to win and strive these out.

i know ive never been disappointed in my keens. love my san jose soft toes and was ecstatic to see they released a heavier duty version of it essentially.

Love Keen. My husband is a contractor and I’m his feet working hard all day.

Would love to add another pair to the ones I already have! Love Keens! I want some San Jose’s

Just a girl looking for new keen work boots 🥾

I have never owned keen I’d love to try them. Ive had almost every other brand and style out there, not only is it expensive but really irritating to spend$200 on a pair of boots to end up getting leg hairs rubbed off and blisters on your feet.

I would love to try a pair of Keens. Seen alot of great reviews lately. Your review was detailed and very informative. Thank you.

Awesome review! Thanks for all the details. Would love a pair like these!

I own a pair of Keens that are 8 years old now would love a new pair. They have been amazing!

I’ve had 3 surgery’s already on my lower back. Having some awesome shoes helps so much to be able to go about my day. I would love to win this awesome giveaway.

I want to use a shoe that is functional and comfortable that I can wear for work and around the house.

@power_tools_junkie

Chicken 🍗

Love my keens, perfect for putting miles on site. Comfy as me Nike’s

Looks like a nice pair of boots!

Would love to ry keen out!

Would love to try a pair of keen boots after trying some of the other brands and still not finding the holy grail boot.

I need a strong and durable boot

Need some tough Keens to wear when I’m crawling around doing flooring. Hello from West Virginia.

I have the same problem with my feet and ankles, they’re usually barking at me halfway through the day. Right now I’m wearing Danner’s with aftermarket insoles but it’s business as usual.

So ima a moc toe guy and so far I’ve tried the red wing Irish setters, and thorogoods. They are both nice boots but i want to try all the big brand moc toes before i make my decision on the brand i will buy for the next how ever many years I’m in the trades. Keen Utility’s Cincinnati line is definitely next on my list after reading your review.

I look forward to getting a new pair of boots, and I’ve wanted to try Keen boots for a while now. I hope that I’ll be able to get them and put them to good use.

Definitely been wanting to try some Keens for a while now! Awesome giveaway!

Those are some pretty sweet kicks. Would definitely be willing to wear a pair as my current boots are chewed out haha

I would love to try these for work boots I’ve been wearing keen hikers for many years love them!

I only have one pair so far but already I am sold! I like that they seem like a great company too from what I’ve seen! I’m happy to support a company like that. @pioneercontractingcc

I like the looks of Cincinnati boot a lot. Combined with the comfort Keen is known for make it a hot seller I bet.

There older pairs seemed to be better. The newer ones haven’t been able to last a year without some sort of stitching or rubber to start coming loose.

Ive been wanting to try out some Keens!

I have loved my last 3 pairs of keens, great fitting boot

I am a window installer so comfort is everything when climbing on ladders all day, and still needing a steel toe for maximum protection. I’d love to try a pair of Keen’s!

This is some good information, I have a problem with longevity in my work shoes, I just wear them out too fast. I’ve noticed how much my feet have been hurting lately in the work shoes I’m currently in and I’m gonna be trying out the Cincinnati boots because almost everything you talked about applies to me.

Thank you for this article!

Love Keen – been wanting to get a pair of these too! Great review, thanks!

I’m actually in the market for new boots. I have always wanted to try laceups but have gone for cowboy/pullup boots. Let’s see how these Keen work out

In need of an upgrade , current boots are jut about done . So many choices but Keen is for sure the top choice !

Finally wore out my Keen Pittsburgh’s. Definitely will be staying with the Keen utility line!

I’ve been in need of some new boots for a while now. Been using old running shoes since my boots wore out a while back.

I love keen. Really comfortable waterproof and wide

I would love to give these boats a try! I too have flat feet and it really puts a toll on my knees and lower back after working long days

From my own personal construction work to volunteer construction, these would be nice to have! Just ripped a hole in my old work shoes the other day too 🙄

Would love to compare these to the new Twisted X work boots. Super light and super comfy!

Would love to get a pair of Keen’s.

Thanks

Great article Paul. Really appreciate the unbiased opinion. Do you, or Mrs Toolpig rather, have any experience with the ladies boots? My wife has a very narrow heel and finds it difficult to find a well fitting, comfortable boot. Any suggestions?

Been wanting some keen boots for a while now I’d be awesome to own a pair !!

I wear a size 16 do not many choices for shoes. Have to check out their website.

I already own one pair of KEENs but would LOVE to win another. Like you said, different jobs require different boots!

Love Keen boots. Great company too.

Working on cars and walking on concrete all day sure make not only my feet but my body sore at the end of the day.

I’m a concrete finisher and go through 2-3 pairs of boots a year. I would love to put these through the test

Love the look of the boots. I didnt know so many different methods

Love my keen boots! Almost wore through my first pair. Would love to win a pair! Favorite boot by far.

A little late but always great love my KEEN shoes!!!! One of my favorite pairs of shoes to wear.

They look tough… I would love to try them out..

IG wooldridgehomes

I’m on concrete floors at UPS and i’ve been wanting to try a pair of KEEN. I’ve also beat up some really good boots over the years in my landscaping and maintenance. I’ve wore different brands doc martens caterpillar‘s everboot and many others. Some cheap some expensive.

I’m always looking for a comfortable boot. Hopefully I can get the chance to try these Keens out!

I do a ton of work on concrete and love my Irish setters. I had a pair of keen utility shoe but they didn’t hold up in my work environment. I’d love to try a pair of their wedge soled shoes to see how they hold up in comparison.

I heard a lot of good things about Keen boots and the comfort and support they provide, I’d love to get a chance to get a new pair of boots. It’s about time I finally get a new pair as my current boots have seen better days, but even then I still had to buy inserts for my current shoes to help give my feet support. I’m hoping that Keen will be able to provide that, along with a wide selection of different styles of shoes as well.

Would love to try out these boots.

I have some san Jose and I love them but they do not last me to long. I wear my boots from 4am to 10pm most days. I cant wait to get my hands on some Cincinnati I think those boots are going to be the best !!!! Great job describing each boot !!👍

Great review. Keen is easily the best work boot company out there never had to break my in comfortable from the start and the science you they put into their boots are next level.

Great review on the boots. Keen makes some great boots. Would definitely love to win and try these out.

Great boots!

Good review! Would love to try a pair out!

great advice on different situations, I’m still looking for the right pair of work boots. Wouldn’t mind trying these out.

Those Cincinnati boots look like a really nice boot, would love to have a pair of those

Currently wearing redwings 405’s which have worked great for me. I’ve had them for about 16 months and in need of a resole but otherwise the boots are great. I’ll need a new pair while those get resoled/ to swap in and out of. I’ve had my eye on the San Jose’s and now the Cincinnati’s as well. Thanks for the review I’ll definitely be going with one of those 2 for my next pair. @bigbogle

I’de love to try Keen Boots! Ive gone through just about every brand except Keen. The Cincinnati’s look sweet and sound oh so comfortable.

@ca_electrician

I’m always looking for a great pair of work boots! I’ve heard good things about these Keen’s

Hey good stuff…I’ve been eyeing up the Cincinnati for months

Thanks for the review. It’s hard to find a boot company that builds more that one or two styles and tries to fit them to every job. I agree buying the thickest heaviest boot made is not right for every job. Thanks for the break down. Maybe Keen, should have a boot selector app. Also need to put in a plug for size 13 plus guys we need more available and a US 13.5 be great!!!! I plan to try a 13 wide in a med strength boot.

Love Keen boots, the Manchesters are by far my favorite. Would love to have a pair of Cincinnati boots for my everyday job!

Would love to have a great pair of utility boots!!!

Great review. Love the Keen brand. Great company and great shoes. Would love these for my job! 👍🏼👍🏼

I have used Keen for a few years now. I really can’t go any other way. Although I do have some redwings and timberlands, Keens are my go to boots. I would really love to try the Cincinnati boots. Nothing but good reviews on it. Great giveaway.

After reading a bunch of positive comments. I decided to try out the val d’or (canadian model name) that were on liquidation. Even though they were steel tow, I found them more comfortable then my composite toe timberland pro.

I love my Keen sandals for the comfort and durability! I’m looking for a pair of work boots and have looked at the Keens before, but this article pretty much cemented it for me. I see a pair of Cincinnatis in my future!

Awesome boots! Would love to win a pair

Would love to test drive a pair!

You always have great advise keep it up!

A nice pair of boots for work around the house is the one thing I haven’t picked up. The Cincinnati style boot is a dang nice looking boot. Would love to finally elevate my footwear game

Love the keen work boots, then make the day go by way faster.

I’ve ruptured my Achilles playing sports and I need good comfortable work boots. The Keen boots that have the flex built in near the toes seem like the best for me. Anyways , looking forward to winning a coupon to get some badly needed boots, Thanks Paul…😁👍

I just ordered a pair of Cincinnati’s last week, although a second pair would definitely be appreciated. Thanks for your reviews and insight, Paul. Hope you’re doing well.

@aliv75

I need a boot-shoe with good arch supports and high enough to support my ankles weakened by an old basketball injury. I’ve gotten cheap boots that don’t last and wound up putting multiple inserts in to gain relief. The search continues… It would be nice if Keen solved it for me.

Thank you for the review those Cincinnati are beautiful bless me with a pair

Very insightful article. I always enjoy the content, keep up the good work!

would love a new paur of keen boots! electrician in the NWT, Canada here.

I’ve heard a lot of great things about Keen’s utility boots from guys in many trades. Was planning on getting some for my next pair. Thanks for the honest reviews!!

Would love to try a pair of Philadelphias

Would love to try these out!

I have only worn Carhartt boots my years of working as a general co tractor. And I have paid for it, I decided to buy a pair of keen work boots and it was life changing, my feet and ankle and knees thank me now!

Great giveaway and review. Sounds like a boot company we should give a try. Quality and comfort don’t always go hand in hand. That is what intrigues me. Thank you

I’m in the market for a new pair of boots, a pair of Cincinnati’s would help me out a lot!!

Would love to have the Tacoma/Glendale boots!!

Need heavy duty boots for work, and am in need of new boots!

Will be checking these out online!

The Cincinnati Boots are very comfortable loookg and stylish! Ibwouosnlove to have a pair

Omg, the women’s options are awesome! Also, the floor of my workshop isn’t insulated. I hope you’re right about these boots because all those layers will make winter work more comfortable!

Haven’t tried a pair of keens yet. So many options I’m not sure where to start. This will give me a good starting point.

I’m glad to hear a review of all of these. I have been looking at the Manchester’s for light duty tasks. I was anticipating the release of the Cincinnati boot for my day to day to help with some foot trouble. Love Keen boots always my first choice.

I’ve heard a lot of great reviews of keen boots I just could never really afford a pair so I end buying those $40 boots every few months that kill your back and feet.

I love my Keens, I have the Braddock lows. I do like the comfort and durability that they offer.

Great Review!

Would love a pair of San Jose’s !

Would Love to try a pair. The old Vans are comfortable, but aways hear great stuff about Keen from my buddies that wear them. I need to join the Keen family.

This is a great review. I love keen boots and have had multiple pairs over the years. I too am in search of the holy grail of boots and have been wanting to try on the new Cincinnati’s. I lreally liked the san jose that ive had but without the water resistance they didnt make it into the wet seasons. Still a great boot for the summer. I think thats why in really looking forward to the Cincinnati.

Would love a pair of these boots look awesome!

I had some San Jose’s, which were great until the sole fell off. About 3 weeks in. Got a refund, but never replaced them. It’s a brand I want to like. We shall see.

I would love a pair of the Cincinnati Boots!

I love me some Keens! They have always been a great company to deal with. @fetzner on the grams

Very nice write up! If I wasn’t already a huge fan of keen boots you would’ve made me take notice of them. I have a similar variety from my work that demands different boots for different days. You’re absolutely right you need more than one tool! My feet have been much happier now that I switch boots out every other day!

I have these boots and they are freakin awesome. Very comfortable and I definitely need comfort after breaking both my feet 7 months ago. So just got back to work this week. Bought Keen because I’ve worn Keen for years now so I know they are good. Wore these around the house for a week and then the big test was at work this week. I’m a laborer so my job is definitely tough on the feet. These boots definitely are worth every penny. I highly recommend.

Wow thats Awesome.Keen is A Great Company Love There Product.And What They Do For There Customers

I have worn so many Keen shoes in my life. Sandals. Hiking shoes. Snow boots. All amazing. Nice and wide toe box for me.

I used to always get Sears diehard mock toe boots. When the Keen San Jose’s came out I was sold comfy, light, and the grip is amazing. My scope of work is changed no longer inside I need something with a beefier upper and a super comfy sole, I have had 4 pairs of the San Jose, definitely a great boot. The Cincinnati is my next destination, Keen does a great job solving problems for trades people. I have complete faith that any Keen boot in its proper setting will amaze you. Excellent review @toolpig

I would really like to try a pair of the San Jose’s. They look awesome!

Perfect timing for this giveaway! I need a new pair of work boots to replace my keens that I am currently wearing.

I like the keen boot line a lot but have generally purchased red wing “wing shooters” or other style moc toe boots within that range, I like the larger toe box of the boots. I also always use a wool insole to keep the stink away and pad the footbed a bit more. Haven’t had the chance to try out the Cincinnati boot but I like the looks and the style of construction. I’d definitely be willing to give them a try.

Sounds like an amazing boot. Just started using Keen boots just a year and a half ago and my Detroit’s have taken a beating but are still my favorite boots to wear.

These boots looks amazing and my Brother Eric could really use them right now! I will definitely look into Keen for my next pair of work boots.

I work in construction sales in NYC where I use the subway and travel by foot jobsite to jobsite. This equates to roughly 30 miles on foot a week, and my current Keen boots have been a Godsend. These things have seen their fair share of concrete, are lighter and more comfortable than previous boots I owned. Looking to check out what the Cincinnati boot is all about!

As soon as this boot came out on the market I wanted it, and I’ve followed your review closely! Thank you for that.

I like the flat sole and the design is nice because it doesn’t look like a hiking boot. The price is kinda high for my pockets, but such is life lol

I currently rock some a pair of keen hiking boots on the job which while comfy are not exactly ideal for hardscaping. Definitely considering upgrading to some of these!

I’ve been eyeing these boots up for a while now because of all the insta reviews and what other people have had to say about them. Fingers crossed!

Thanks for the info and review on Keen boots! I currently am using Irish Setters by Redwing but we only buy Keen work boots for my wife!I appreciate the details on the 3 boot construction methods. I love the Cincinnati boots and would love to own them one day. My work takes me all over the place, outside and in, and exposes me to all kinds of environments and conditions. I go through pairs of boots faster than I would like but I would love one good durable pair of boots! The Cincinnatis might be it! Please pick me!

Nice review! Can’t wait to try these out!

These boots look amazing would love to own a pair 👌🏽

I wear Keen both at work and outside of work. Good boots for everyday, hiking, work and all!

Really love Keen boots. Very comfortable

Would love to try a pair of Keens.

I would love to try Cincinnati. I’m a framer I think it would be a good pair of boots!

Thank you so much for you wisdom and insight into this shopping Headache! Lol Definitely interested in the Manchester’s And the Cincinnati’s!

Again Thank You 🙏

Ahh, comfortable work boots! My hubby needs these!!! The ones he buys always rub his feet until he has blisters 😩. I always ask if that’s just how work boots are, now I know it’s just how cheap ones are. Fingers crossed I’m chosen, I would be wife of the year lol!!!

These are nice boots been following for a long time

I like there hiking boots but never had a chance to use keen work boots. This has peaked my interest

Keen boots look solid and tough but still look very comfortable. I’ve never owned a pair but I’ve heard nothing but gold about them!

They definitely have the comfort out of the box nailed

Never owned keens before, but I have been waiting for these to come to Canada. Looks like a solid boot!

O bought my first keens in December. They have been the best boots I’ve worn. I’ve had problems with my feet for years and have really enjoyed these boots.

Really in-depth review. Also really liking the mobile version of this website good job!!

@nicholas_fn_tanner

I love my Keens that I Wear on LDC Projects and have been eying the Cincinnati’s they look like the right fit for my feet i have flat feet and need a comfort boot that is light weight so that is awesome to read your reviews on them all! Thanks For the breakdown between them all!

These look like some well constructed boots and would really make my feet happy at work.

Never owned a pair of keens always wanted to try them ! @j.frias416

Look/sound great, very interested.

Have owned 3 pairs of keen. Love them. My Manchester’s are getting pretty worn out and these new boots would be awesome

This is a great review. I love keen boots and have had multiple pairs over the years. I too am in search of the holy grail of boots and have been wanting to try on the new Cincinnati’s. I lreally liked the san jose that ive had but without the water resistance they didnt make it into the wet seasons. Still a great boot for the summer. I think thats why in really looking forward to the Cincinnati.

Great boots great company

Thanks for doing this, would be an amazing upgrade to what I am wearing now!

Only boot I will wear!

The only boot I will wear!

Nice write up about boots in general. I couldn’t agree more about boots being an important tool that we use everyday. I don’t understand guys who buy cheap boots and have feet problems. Did you really save money? Is the pain worth it? I’m like you, I’ve worn almost every major brand of boot and LOVE Keens. I think I’m on my 6th pair now. I love the Pittsburghs. They fit me well and serve a variety of applications. I also have the Logandales. Hopefully I’ll get another pair!

jeff_t_dadof3 on Instagram

I never owned a pair of keen work boots, regardless of the outcome of this giveaway they might be my next purchase. My current pair have seen better days. I’m a carpenter in Denver Colorado, I’ve been in the trade for around 12 years now. I’m currently out of work as a result of the coronavirus hoping to be back to work soon.

Love Keen boots and the company! Would love to try the Cincinnatis!

Yo what’s up tool Pig I need these boots man I just recently became the new estimator for a construction company in Bellflower California and I would really love to kick these boots around. @ Rogg73

Thanks

I have read nothing but good things about the Cincinnati. Would love a pair!!!

Another great take. Keep these reviews coming

I wear through every pair of boots I get. Keen is up next on the list to try!

Definitely want to try a pair of Keens

Super interested in trying Keen boots!

I like wearing work boots for their support but these seem to be made very well and comfortable!

Woo love to have a pair of new boots.Utility Cincinnati would be my next pick.

Keens save your knees.

Send me your information so I can send you a winning code from Keen Utility!